Raw materials are shifted from the raw materials inventory to the work-in-progress inventory in most manufacturing plants. One or more production departments are involved in the work process, where labor and overhead turn raw materials into completed commodities. Figure 6.8 illustrates how the costs in each pool are allocated to each product in a different proportion. COGS is not addressed in any detail in generally accepted accounting principles (GAAP), but COGS is defined as only the cost of inventory items sold during a given period. Not only do service companies have no goods to sell, but purely service companies also do not have inventories.

Have you ever opened your banking app and been struck with a wave of panic? Or found yourself staring at your phone screen in utter bewilderment, wondering where all your money went? These are all-too-common experiences that can be easily remedied with a well-implemented product costs consist of product costing system. Put simply, understanding the costs of developing a product, feature, or update helps you make more informed decisions throughout the product lifecycle. The age of AI is set to revolutionize accounting, not replace accountants.

What Is an Example of a Product Cost?

This can help them to make more informed production decisions and improve their profitability. Once you calculate all these costs, divide them by the total number of units produced to get your final product cost. This number is essential because it will help you determine how much you need to charge for your product to make a profit. Several methods are used to calculate product cost, including direct, full, and traditional costing methods such as absorption and activity-based costing.

This treatment differs from period costs, including fixed, underselling, and administrative expenses. This process usually relates to short-term product and sale-price decisions. Product cost appears in the financial statements since it includes the manufacturing overhead that is required by both GAAP and IFRS. However, managers may modify product cost to strip out the overhead component when making short-term production and sale-price decisions. Almost every physical product involves direct materials, direct labor, and overhead costs, which might include indirect labor and additional expenses like utilities and equipment depreciation.

Calculating the Product Cost

The cost of sending the cars to dealerships and the cost of the labor used to sell the car would be excluded. This formula incorporates all the components of product costs and adds them together. If one of those components is absent, companies can ignore them in the calculation.

- Do you ever find yourself curious about how your favorite products are priced?

- When the product is sold, the costs move from the finished goods inventory into the cost of goods sold.

- The total cost of production is divided by the number of units produced to arrive at the cost per unit.

- In managerial accounting, the term “product cost” refers to the overall production cost that is incurred to manufacture products or provide services.

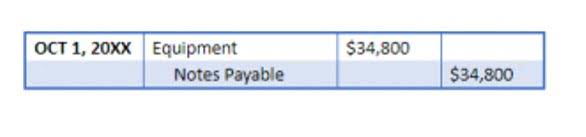

COGS only applies to those costs directly related to producing goods intended for sale. Harem manufactures ladies’ clothes using fine cotton imported from India. Here is a breakdown of how they do it for their most profitable model, KT-AWD.

LogRocket generates product insights that lead to meaningful action

For example, airlines and hotels are primarily providers of services such as transport and lodging, respectively, yet they also sell gifts, food, beverages, and other items. These items are definitely considered goods, and these companies certainly have inventories of such goods. Both of these industries can list COGS on their income statements and claim them for tax purposes.

Once you’ve arrived at an optimal budget for materials, add the labor cost to the total. This includes wages for employees or contracted workers involved in making the product. Cost of goods sold is the direct cost of producing a good, which includes the cost of the materials and labor used to create the good.

How Should Business Owners Set Their Prices?

This is because they don’t seem to directly impact the products being manufactured. Consider your inventory carrying costs as a manufacturer, including storage, insurance, maintenance, and, if necessary, disposal. Will you hire a fulfillment house, or will you transport your products yourself? All of these questions should get considered when establishing your final price. Your time should undoubtedly be taken into account and factored into your cost.

They pay $1,000 for rent, $500 for utilities, and $250 for instrument maintenance. Additionally, external factors like Product design, complexity, and supply chain disruption impact the pricing/ cost structure of the product. It also enables companies to evaluate their performance and make necessary adjustments to improve profitability. There were fewer machine hours than estimated, but there was also less overhead than estimated. There were more requisitions than estimated, and there was also more overhead.